About Us

Founded in 1995 in Taichung, Taiwan, Xin Cai has leveraged the strengths of central Taiwan’s industrial network to specialize in high-quality bag manufacturing. From the beginning, we have focused on building a strong foundation in craftsmanship and production processes.

As our business expanded, we established operations in Dongguan, Shanghai, and Guangzhou—integrating design and manufacturing resources to successfully enter the European, American, and Asian markets. Over the years, we’ve developed long-term partnerships with numerous international brands.

In response to the rise of digitalization and e-commerce, we began accelerating our sampling and supply capabilities in 2019. By adopting smart manufacturing and eco-conscious processes, we strengthened our real-time product development and sustainable adaptability.

In response to the rise of digitalization and e-commerce, we began accelerating our sampling and supply capabilities in 2019. By adopting smart manufacturing and eco-conscious processes, we strengthened our real-time product development and sustainable adaptability.

Looking ahead to 2026, we are committed to further advancing AI-driven applications and smart supply chain integration. By combining design thinking with sustainable principles, we aim to deepen co-creation with brand partners.

Transitioning from “manufacturing” to “smart manufacturing,” we go beyond delivering products—we engage in brand strategy to create market-driven, design-distinctive, and sustainability-focused solutions.

Our goal is to become the most trusted long-term partner for every brand we collaborate with.

Our Service

Sampling & Prototyping

We help bring your ideas to life with fast and precise prototyping support.

Design Development

From structure to function, we offer practical design suggestions tailored to your brand needs.

Material Sourcing

Based on your budget, style, and functionality, we recommend suitable fabrics and hardware.

Flexible Production Quantities

Ideal for startups and niche brands-we offer flexible MOQs with consistent quality

Customized Service

Our experienced team specializes in a wide range of bag styles — from casual backpacks and canvas totes to premium leather goods. We tailor each product to meet market demands while ensuring consistent quality for your brand.

Shoulder Bag

Backpack

Chest Bag

Various leather bags

Additional accessories

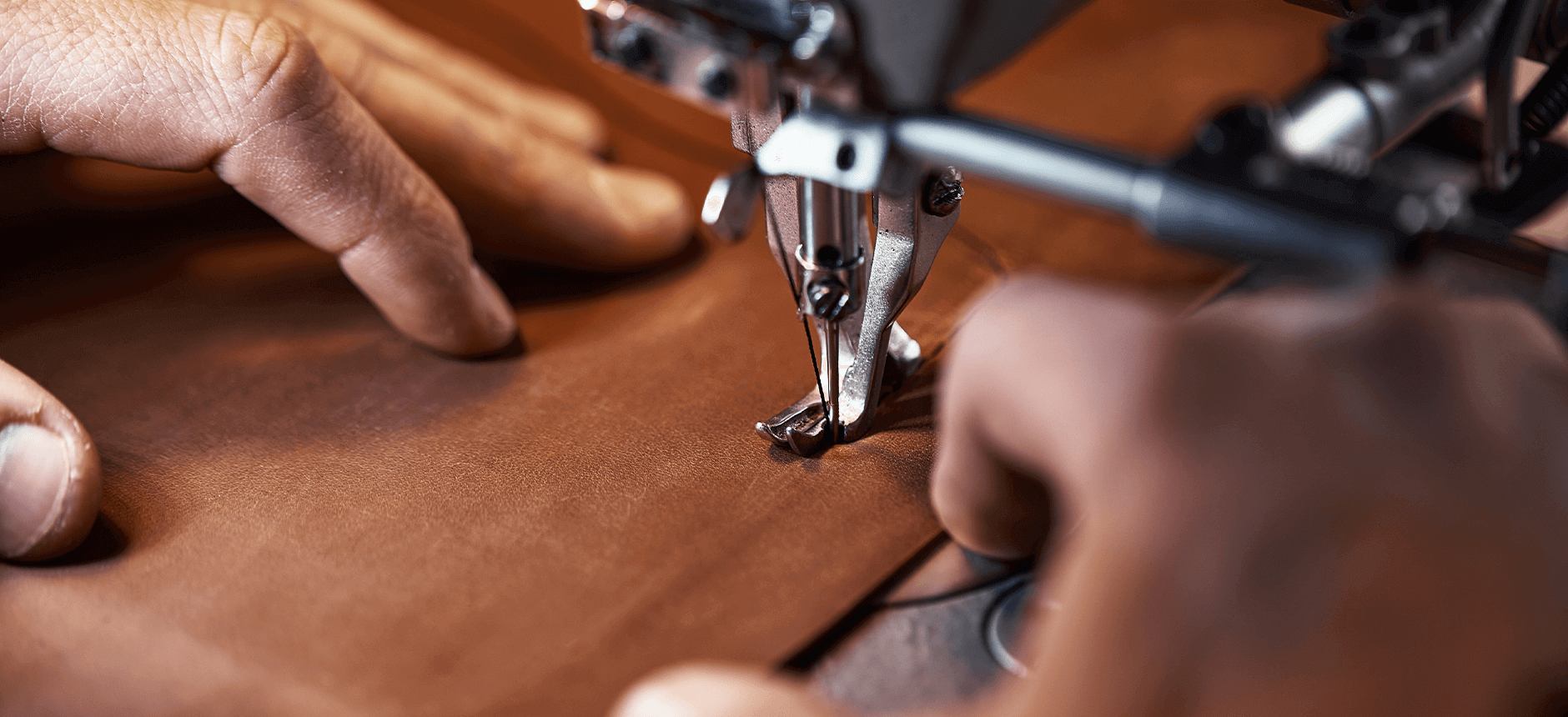

Craftsmanship

Jun 28.2025

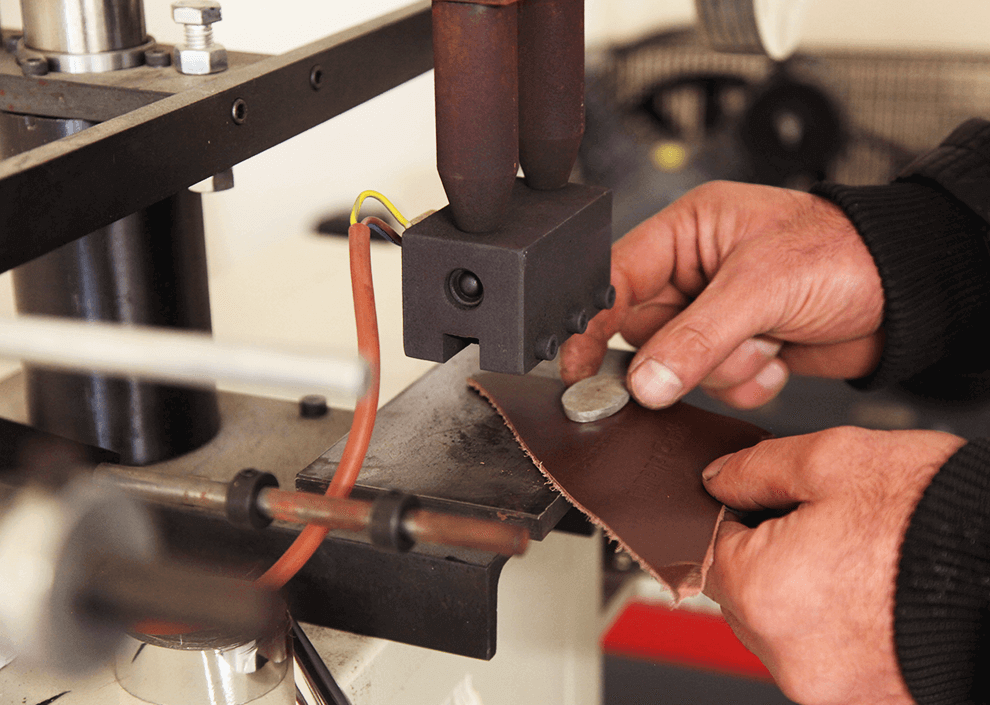

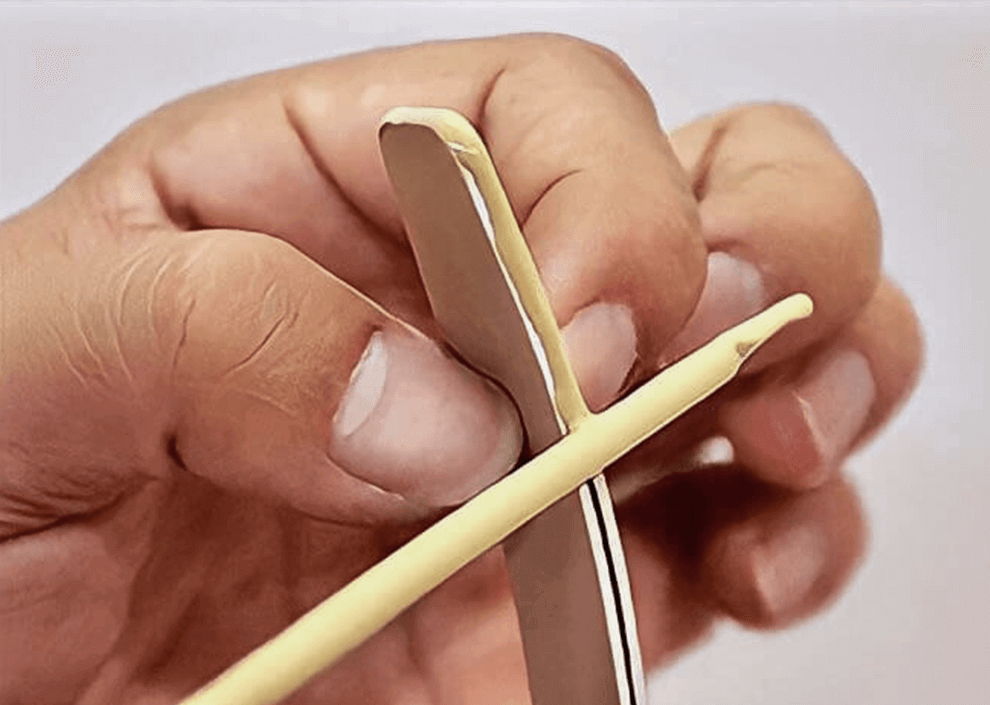

Debossing Technique

Debossing Technique: Adding Depth, Craftsmanship, and Brand Identity Debossing is a refined surface treatment that uses heat and pressure to imprint patterns, logos, or text onto leather or fabric materials. This technique creates elegant, recessed impressions that add a tactile, three-dimensional texture—enhancing both the visual sophistication and the perceived value of the product. Among the many detailed processes in bag manufacturing, debossing plays a key role in embodying a brand’s spirit and adding soul to the final product. ________________________________________ Key Features of Debossing: •Strong Dimensional Effect The recessed patterns offer a pronounced depth, showcasing craftsmanship and a premium finish. •No Additional Inks or Pigments Required Blind debossing preserves the natural tone of the material, creating a minimalist aesthetic and subtle brand signature. •Wide Material Compatibility Suitable for genuine leather, microfiber leather, PU synthetic leather, canvas, and more. •Highly Durable Unlike printed or labeled logos, debossed details do not fade or peel, retaining their clarity and integrity over time.

Jun 28.2025

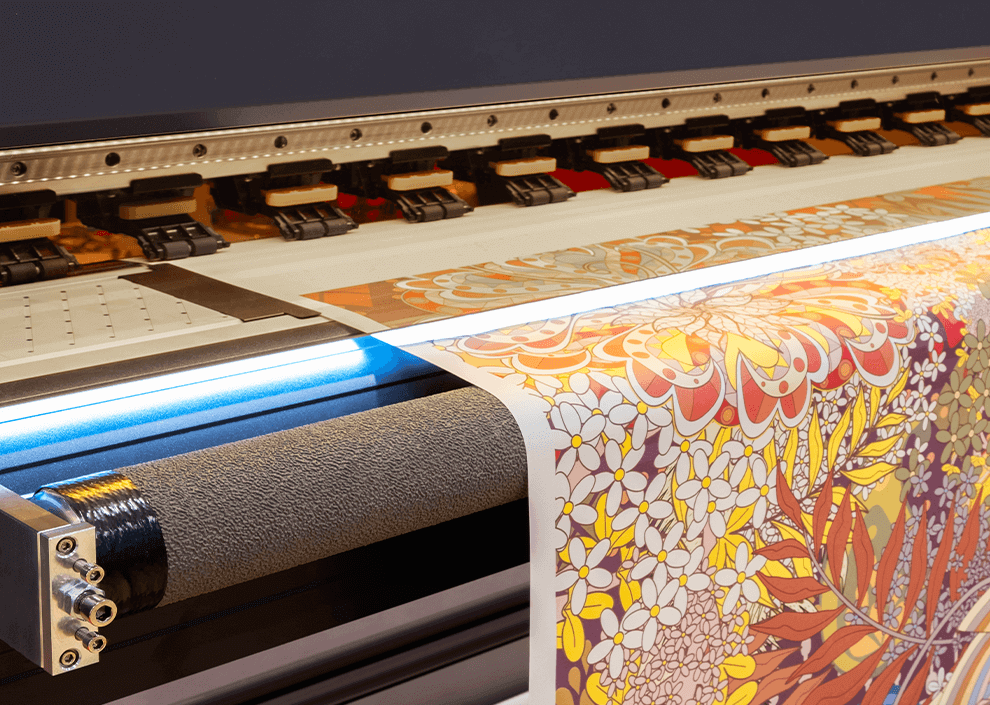

Digital Printing: Unlimited Color, Unlimited Creativity

Digital Printing: Unlimited Color, Unlimited Creativity With advancements in textile technology and printing processes, digitally printed fabrics have become an essential medium in modern bag manufacturing. Full-code high-resolution digital printing breaks traditional color limitations, allowing precise placement and vivid reproduction of graphics and brand logos. The result: crisp visuals and accurate alignment, perfect for full-coverage designs and customized projects. ________________________________________ High-Resolution Imagery with Exceptional Detail Digital printing supports full-color patterns, gradient transitions, intricate textures, and hand-drawn styles. Unlike traditional screen printing, there are no color count limitations, making this technique ideal for brand collaborations, seasonal editions, and artistically inspired collections. Eco-Friendly Inks and Sustainable Fabric Options To meet growing environmental demands, we offer options for water-based eco-inks and recycled textile bases—minimizing environmental impact while embracing sustainable design principles. Colorfast, Durable, and Resistant to Fading Our digitally printed fabrics undergo standardized treatment and field testing to ensure excellent color fastness and abrasion resistance. Even with frequent use, folding, or carrying, the prints remain sharp and vibrant over time, maintaining a fresh appearance.

Jun 28.2025

Computerized Embroidery

Computerized Embroidery: Precision Craftsmanship That Brings Designs to Life As manufacturing techniques evolve, the modern bag industry has embraced high-precision computerized embroidery, transforming bags from simple carriers into canvases of brand identity and design expression. Using fully automated, high-density embroidery machines, each pattern is rendered with exceptional accuracy. The result: densely packed stitches that create rich textures and dimensional details. The finish is refined, vintage-inspired, visually striking, and built to last. ________________________________________ Flawless Brand Detail Presentation Delicate lines, logos, lettering, and symbolic motifs can all be clearly depicted. Thread colors are fully customizable to match brand guidelines, delivering vibrant, layered visuals that enhance the overall appeal of the bag. Expertise in Multi-Material Embroidery Our team is experienced in handling a wide range of base materials—leather, canvas, nylon, polyester, and more. We adjust stabilizer thickness, stitch density, and needle techniques according to the material’s elasticity and structure, ensuring embroidery doesn’t distort or damage the base fabric, and prevents wrinkling or pulling. Compatible with Mixed-Media Crafting Embroidery can be seamlessly integrated with other finishing techniques such as debossing, digital printing, mixed-material patchwork, edge binding, piping, and 3D woven labels. This versatility makes it an ideal choice for limited editions, co-branded collections, and signature brand series.

Jun 28.2025

Traditional Handcrafted Silkscreen Printing

Traditional Handcrafted Silkscreen Printing: A Timeless Art of Craftsmanship Silkscreen printing is a long-established printing technique, with traditional handcrafted silkscreen printing representing the pinnacle of artisan skill and creative design. Through manual operation, patterns are carefully transferred layer by layer onto fabrics or leather, delivering rich, saturated colors with vivid layering and a tactile, handmade feel. This process adds uniqueness and a warm, human touch to bag products. ________________________________________ Process Overview: 1.Screen Preparation Based on the design, photosensitive emulsion is applied to create separate screens for each color. Each color requires an individual screen to ensure precise color separation. 2.Registration Alignment Manual printing demands high precision; each color layer is meticulously aligned by skilled artisans, ensuring seamless pattern continuity. Patience and experience are critical to flawless registration. 3.Layered Printing Ink is manually pushed through the screen onto the material with a squeegee, building colors layer by layer. This results in vibrant hues with distinct texture and depth, embodying a rich handcrafted quality. 4.Drying After printing, materials undergo either natural air drying or machine curing depending on the substrate, to fix the design and enhance durability. ________________________________________ Key Features: •Rich Color Saturation & Strong Dimensionality The thick ink layers from hand printing offer exceptional color vibrancy, clear textures, and detailed fullness. •Capability for Complex and Artistic Patterns Suitable for gradients, totems, vintage prints, slogans, and other irregular designs rich in artistic expression. •Washable and Fade Resistant Uses specialized inks and fixation processes to ensure durability, ideal for frequently used canvas and nylon bags. •Emphasizes Artisan Warmth and Craft Value Each print is hand-crafted by skilled artisans, resulting in subtle variations and unique textures impossible to replicate by mass machinery.

Jun 28.2025

Edge Painting

Edge Painting: The Essential Finishing Touch for Premium Bags Edge painting is a crucial craft in high-end bag manufacturing, primarily applied to leather edges, seams, and outer frame trims. It serves as the final soulful refinement of a finely crafted bag. Suitable for various fabric and leather surfaces, this technique uses four-color separation printing to deliver clean patterns and brand logos with delicate craftsmanship and stable color quality. ________________________________________ More Than Just Aesthetic Appeal After leather pieces are cut, their edges expose raw fibers and rough surfaces. Without proper treatment, these edges are prone to fuzzing, water absorption, delamination, or cracking over time. Edge painting seals these exposed fibers, enhancing durability and water resistance. It also smooths and refines the overall lines, elevating the product’s finish and professionalism.

Jun 28.2025

TPU Hot Stamping

TPU Hot Stamping: A Signature Technique that Combines Visual Impact with Functional Value TPU hot stamping is a standout finishing technique that fuses visual appeal with practical functionality. By applying controlled heat and pressure, patterns, text, or brand logos are heat-transferred and firmly bonded onto the surface of the bag. This process enhances material details, creating strong brand recognition and a trend-forward aesthetic. TPU (Thermoplastic Polyurethane) is an eco-friendly elastomer material free of plasticizers. It offers excellent flexibility, abrasion resistance, clarity, and moldability. When used in bag manufacturing, TPU not only enhances the product's performance and appearance but also aligns with today’s sustainability and environmental standards. Using heat press technology and custom molds, TPU film can be precisely applied to various common bag materials such as canvas, nylon, microfiber leather, and polyester. With strong adhesion and stability, the stamped designs remain crisp and detailed—offering outstanding durability and long-term performance. TPU hot stamping offers diverse visual effects, including: •Matte finishes •High-gloss shine •Metallic tones •Transparent embossed effects This technique not only adds visual depth to the bag but also powerfully communicates the brand identity, design language, and unique style.

Material

Jun 28.2025

Nylon: Versatile Synthetic Fabric for Functional and Stylish Bags

Nylon is a synthetic fiber fabric widely used in various bag designs. As a professional bag manufacturer, we select multiple high-grade nylon materials tailored to different bag functionalities, such as lightweight construction, water repellency, tear resistance, and high abrasion durability. This enables brands to create practical products that combine both performance and aesthetic appeal. ________________________________________ Material Characteristics: 1.Lightweight and Flexible Nylon fibers are fine and lightweight, significantly reducing carrying burden even for large-capacity backpacks, making it ideal for travel, commuting, and outdoor sports collections. 2.High Abrasion and Tear Resistance The strong molecular structure of nylon endures long-term use and daily friction without fuzzing or damage, suitable for functional bags requiring high-strength support. 3.Excellent Water-Repellent Finish Adaptability Nylon fabric surfaces readily accept water- and oil-repellent coatings such as PU, TPU, or silicone finishes, offering robust protection. It is commonly used in outdoor bags, sports bags, and weather-resistant designs. 4.Stable and Uniform Dyeing Nylon fibers support high-quality dyeing, producing vibrant and saturated colors that resist fading. This makes it perfect for colorful, color-blocked, or fashion-forward bags. 5.Compatible with Various Craft Techniques Nylon integrates well with embossing, embroidery, TPU hot stamping, and high-frequency welding, enhancing design flexibility and innovation. ________________________________________ Nylon is more than just a symbol of functionality; it is a vital material that combines lightweight, practicality, and aesthetics in modern bag design. With different weaving methods such as plain weave, twill, ripstop, and grid patterns, as well as various surface treatments, nylon can convey styles ranging from minimalist tech to military ruggedness, offering brands greater flexibility and depth in material selection.

Jun 30.2025

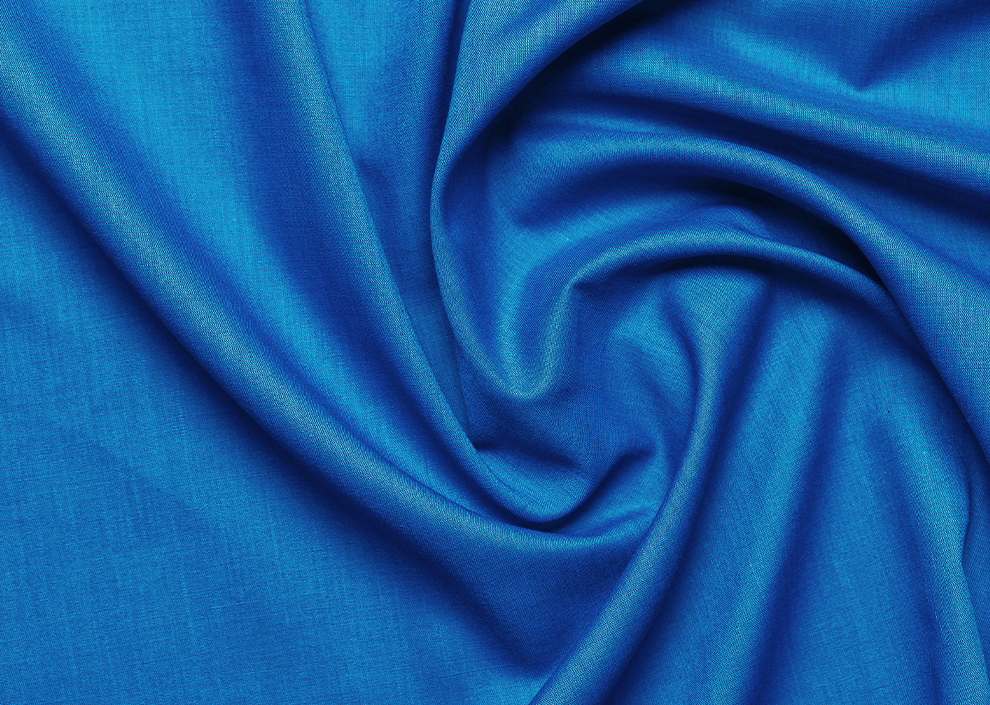

Canvas: Durable, Natural Fabric with Timeless Appeal

Canvas is a sturdy woven fabric primarily made from cotton or cotton blends, known for its natural texture, abrasion resistance, and firm structure. As a classic and enduring choice for bags, it remains a staple material in the industry. As a professional bag manufacturer, we select various weights and finishes of canvas fabrics according to product characteristics and brand styles. By integrating modern craftsmanship, we bring out both classic and innovative aspects of canvas. ________________________________________ Material Characteristics: 1.High Abrasion Resistance & Structural Firmness Canvas features a dense weave and thick yarns, offering excellent tensile strength and durability. It maintains bag shape over long-term use, making it especially suitable for medium to large tote bags, handbags, and daily functional bags. 2.Natural Texture with Soft Touch The inherent natural grain and matte finish of cotton fibers add a rustic and approachable feel. Combined with dyeing treatments, canvas can evoke atmospheres ranging from artsy, workwear, vintage, to street style. 3.Excellent Adaptability for Various Craft Techniques Canvas supports embroidery, digital printing, silkscreen printing, embossing, computerized embroidery, leather patching, and more. It serves as a highly versatile design base and pairs well with leather, metal, nylon, and other materials to enhance visual layers. 4.Surface Treatment for Water Repellency Though natural cotton fabric, canvas treated with PU, wax dye, or water-repellent coatings improves weather resistance and extends bag lifespan, making it suitable for everyday and outdoor use. 5.Eco-Friendly and Sustainable Options We offer organic cotton canvas, recycled cotton canvas, and natural dye fabrics to help brands implement sustainable concepts and develop environmentally conscious product lines. ________________________________________ Canvas is a material with soul, capable of carrying the designer’s narrative and evolving alongside the user over time.

Jun 30.2025

Genuine Leather: A Timeless Material of Prestige and Character

Genuine leather refers to premium-quality material derived from natural animal hides, processed through professional tanning techniques. As an irreplaceable classic in bag manufacturing, it offers unique grain patterns, a supple touch, and breathable properties. Over time, genuine leather ages gracefully, enhancing the bag’s elegance and individuality. ________________________________________ Material Characteristics 1.Natural Grain and Unique Texture Each piece of leather retains the pores and fine lines of the original hide, making every bag one of a kind. Through various tanning methods (e.g., vegetable tanning, chrome tanning), it can express a wide range of aesthetics—from sleek sophistication to rugged vintage. 2.Soft Yet Durable Flexibility Leather provides excellent elasticity and adaptability, giving bags a warm, refined feel while enhancing structure and comfort. 3.Breathable and Moisture-Absorbing Natural breathability allows genuine leather to regulate humidity and reduce stuffiness, maintaining bag quality and extending product life during daily use. 4.Aging with Beauty High-quality leather develops a unique patina over time—a soft sheen and rich character that reflects the owner’s usage, making each item more personal and storied. 5.Repairable and Maintainable With regular cleaning and care, genuine leather retains its softness and luster, allowing the product to remain in optimal condition for years. ________________________________________ Common Types of Genuine Leather by Animal Source •Cowhide Most widely used, offering thick, durable, and diverse textures. Suitable for various bag styles from refined to rugged, depending on treatment. •Sheepskin Lightweight, soft, and smooth. Ideal for luxury handbags and accessories; delicate in feel but less abrasion-resistant. •Pigskin Coarse and breathable with prominent grain. Highly durable and commonly used in practical, cost-effective bags and shoes. •Horsehide Dense, glossy, and tightly grained, offering strong resistance and a bold appearance—suitable for structured bags needing durability. •Crocodile Leather A symbol of luxury. With its distinctive scales and premium price, it’s often used in high-end designer bags. •Python Leather Known for unique scale textures and depth. Smooth, with a statement look for accent pieces or fashion-forward designs. •Ostrich Leather Features raised quill follicles for a distinct tactile quality. Valued for high-end applications. •Buffalo Leather Thick and tough with pronounced, rugged texture. Ideal for vintage-style and durable bag collections. ________________________________________ Popular Tanning and Finishing Techniques •Vegetable Tanning Eco-friendly, using plant-based tannins. Offers a rich, natural tone and firm yet flexible texture. •Chrome Tanning Fast and versatile, resulting in smooth leather with vibrant colors—suitable for sleek and refined styles. •Other Finishes: Includes brushing, embossing, dyeing, and distressing to create vintage effects, polished surfaces, or unique patterns. ________________________________________ Potential Drawbacks of Genuine Leather 1.Higher Cost Due to its natural source and complex tanning process, genuine leather products are more expensive than synthetic alternatives. 2.Maintenance Required Needs regular care (moisturizing, waterproofing, sun protection) to prevent cracking, discoloration, or hardening. 3.Lower Water Resistance While moderately moisture-resistant, leather can absorb water, leading to deformation, mold, or color changes over time. 4.Heavier Weight Denser than synthetic materials, adding noticeable weight—especially for larger bags. 5.Ethical & Environmental Considerations Being animal-derived, some consumers may have concerns about animal welfare and the ecological impact of the tanning process.

Jun 30.2025

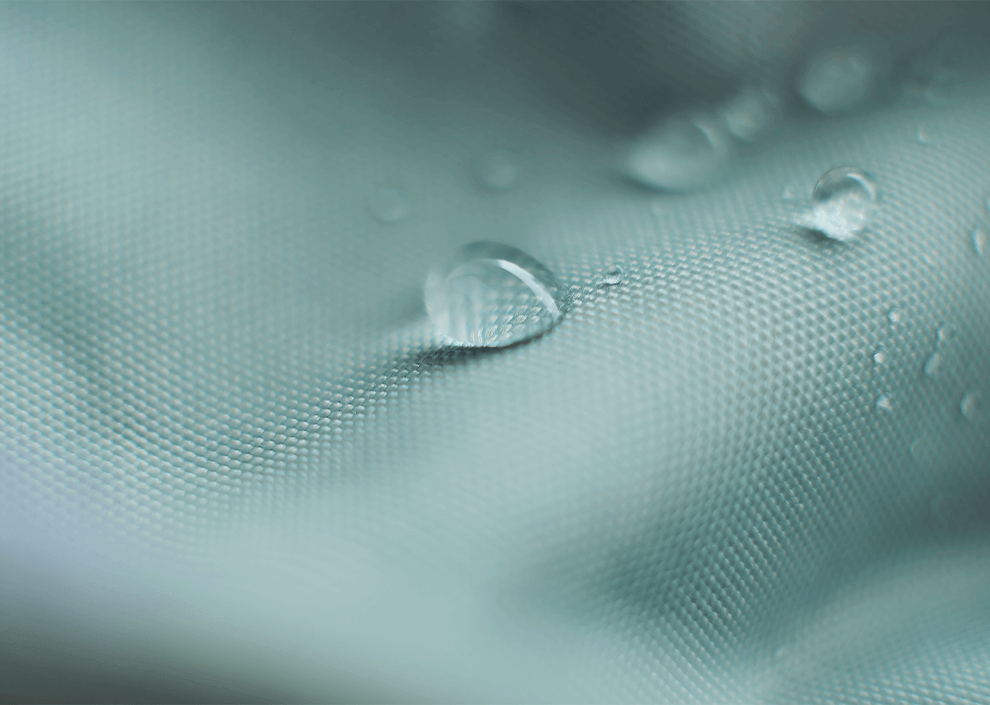

Technical & Specialty Fabrics: Where Performance Meets Style

Technical fabrics and specialty materials are essential components in modern bag design, offering the perfect blend of durability, protection, and aesthetics. These advanced textiles not only enhance functionality but also elevate the visual appeal and brand value of each product. ________________________________________ Key Fabric Types & Features 1. Water-Repellent / Waterproof Materials Coated with PU, TPU, or engineered with special weaving techniques, these fabrics provide excellent protection against rain, spills, and dirt. Ideal for outdoor gear, travel bags, and all-weather designs. 2. Ripstop Nylon (Tear-Resistant Fabric) Constructed with reinforced weaves—often visible as a crosshatch pattern—ripstop fabric dramatically increases tear resistance while remaining lightweight. A staple in military-style and outdoor-performance bags. 3. High-Density Anti-Abrasion Fabric Densely woven and surface-treated to resist scuffs and scratches. Perfect for high-use items such as commuter backpacks and laptop bags, ensuring long-lasting appearance and durability. 4. Breathable & Quick-Dry Materials Made with technical fibers that promote airflow and wick moisture away from the body. These materials are great for gym bags, sports duffels, and designs requiring all-day freshness. 5. Reflective / Luminous Materials Incorporated with reflective yarns or glow-in-the-dark coatings to enhance visibility at night. Combines safety with urban street style—popular in streetwear and athletic collections. 6. Antibacterial & Odor-Resistant Fabrics Treated with antimicrobial agents to inhibit bacterial growth, these fabrics keep bags fresher for longer. Ideal for sports, outdoor, and everyday multifunctional bags. ________________________________________ Advantages of Technical & Specialty Fabrics •Enhanced Performance: Improves resistance to water, tearing, and abrasion, extending product lifespan and reliability. •Versatile Aesthetic Options: Wide range of textures and finishes available, enriching design language and brand differentiation. •Adaptability Across Environments: Suitable for urban commuting, outdoor exploration, or fashion-forward collections. •Sustainability-Ready: Many technical fabrics support eco-friendly design goals, showcasing your brand’s commitment to environmental responsibility.

Jun 30.2025

Polyurethane Leather (PU Leather): Affordable Luxury with Functional Performance

Polyurethane leather, commonly known as PU leather, is a type of synthetic leather made by applying a polyurethane coating onto a fabric base. It closely mimics the look and feel of genuine leather, while offering advantages such as cost-effectiveness, light weight, ease of maintenance, and ethical sourcing. PU leather is a popular alternative to real leather in the bag industry, making it a go-to material for accessible yet stylish designs. ________________________________________ Material Highlights 1. Leather-like Appearance and Texture PU leather has a smooth surface and can simulate a variety of leather grain patterns. It is soft, flexible, and visually appealing, making it an excellent substitute for natural leather. 2. Lightweight & Easy to Work With Compared to genuine leather, PU is significantly lighter. It is also more adaptable to various techniques such as dyeing, embossing, printing, and texturing—ideal for creative and trend-driven designs. 3. Water- and Stain-Resistant PU leather does not easily absorb water or dirt. It is resistant to stains and splashes, easy to clean, and low-maintenance—great for everyday-use bags. 4. Eco- and Animal-Friendly Made from synthetic materials, PU leather avoids the use of animal products. It aligns with the growing demand for cruelty-free and sustainable fashion. 5. Durable and Scratch-Resistant High-quality PU leather has strong abrasion and scratch resistance, offering reliable durability for bags subject to frequent use. ________________________________________ Limitations of PU Leather 1. Lower Breathability Unlike natural leather, PU lacks pores, making it less breathable. Extended wear may cause discomfort in hot or humid conditions. 2. Less Long-Term Durability Although PU is tough, it does not match genuine leather in elasticity and resilience. Over time, it may crack, peel, or degrade under heavy use. 3. Hard to Repair Once damaged, PU leather is difficult to restore. Scratches or surface wear cannot be easily fixed with traditional leather care methods. 4. Sensitive to Environment PU material can deteriorate when exposed to prolonged heat, UV light, or moisture, reducing its lifespan in harsh environments. 5. Less Natural Aesthetic While visually similar to leather, PU lacks the depth, subtle variations, and patina development of genuine hides, making it less appealing to luxury-oriented consumers.

Jun 30.2025

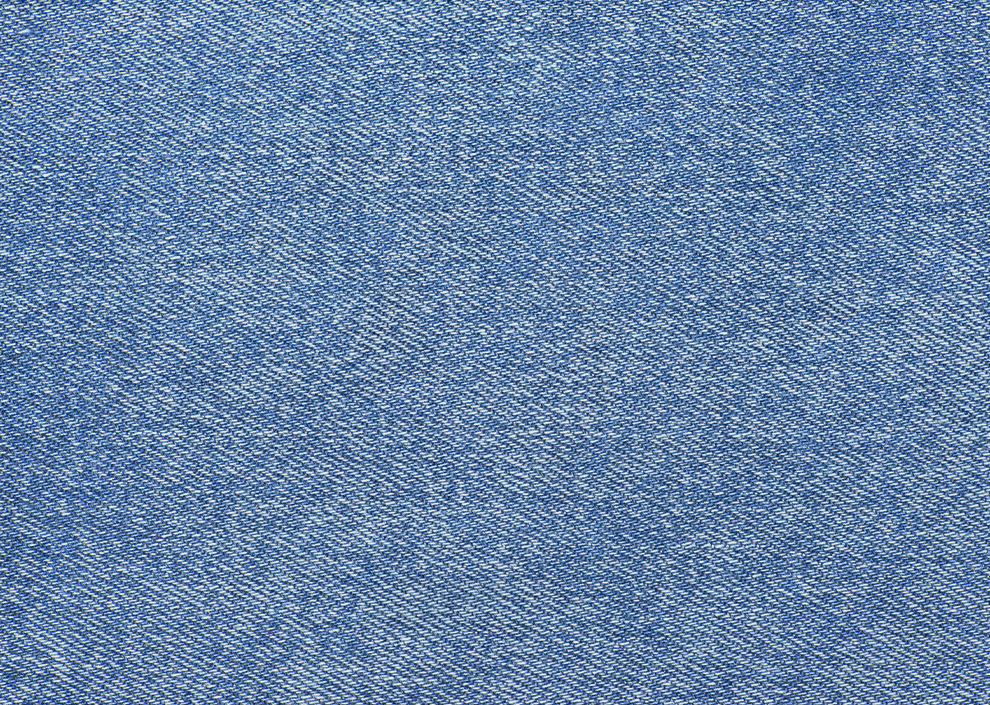

Denim: A Timeless Fabric with Rugged Charm

Denim is a durable twill-woven fabric made from cotton fibers, known for its excellent abrasion resistance and iconic fading characteristics over time. Originally used as a heavy-duty canvas, denim has evolved into a classic material for both fashion and functional bag designs. While indigo blue remains the most recognizable color, modern denim now comes in a variety of shades and finishes, allowing it to suit a wide range of styles. ________________________________________ Material Characteristics 1. Highly Durable & Structurally Strong Woven with thick cotton yarn in a twill pattern, denim offers exceptional wear resistance and tensile strength, making it ideal for daily-use and outdoor-style bags. 2. Unique Fading & Patina Over Time Denim develops a personalized look through natural fading and wear. This evolving character gives each bag a vintage and well-loved aesthetic that reflects the user’s lifestyle. 3. Breathable & Comfortable to the Touch As a natural cotton material, denim provides good breathability and a soft hand-feel—suitable for bags worn close to the body or used frequently. 4. Versatile for Post-Processing Techniques Denim supports a wide range of treatments, including stone washing, distressing, fading, printing, and coating, enabling rich textures and layered visual effects that cater to streetwear and fashion-forward designs. ________________________________________ Drawbacks of Denim 1. Heavier Weight Compared to lighter materials like nylon or canvas, denim is relatively thick and heavy. Bags made from denim may feel bulkier during extended use. 2. High Water Absorbency & Moisture Sensitivity Denim absorbs water easily and dries slowly. Prolonged exposure to moisture can lead to mildew, odors, or fabric degradation. 3. Color Transfer Risk As denim fades, its dyes may rub off and transfer to clothing or other accessories. Users should take care when wearing or storing denim items. 4. Limited Stain Resistance Unlike synthetic fabrics, denim is more prone to stains and requires careful washing. Improper cleaning may result in discoloration or set-in marks. 5. Wrinkle-Prone & Shape Deformation Due to its cotton composition, denim can wrinkle or lose its shape after long periods of use or folding, which may affect the bag’s structured appearance.

Jul 09.2025

Microfiber: The Premium Alternative to Genuine Leather

Microfiber leather is a high-grade synthetic material made by combining ultra-fine polyester fibers with polyurethane (PU) through advanced manufacturing processes. With fibers much finer than human hair, this innovative material offers a soft, refined, and durable texture that closely resembles natural leather—while also providing eco-friendly, low-maintenance benefits. ________________________________________ Material Characteristics 1. Ultra-Fine and Dense Fiber Structure Constructed with micro-scale fibers, microfiber leather delivers exceptional softness and a smooth, high-end feel. Its dense structure enhances visual and tactile sophistication. 2. Excellent Abrasion and Tear Resistance Engineered for durability, microfiber leather withstands frequent use and resists wear and tear—ideal for high-traffic bags like totes, backpacks, and daily carry styles. 3. Superior Breathability Compared to traditional PU leather, the microfiber structure provides better ventilation, improving user comfort during prolonged use. 4. Eco-Friendly and Plasticizer-Free Manufactured using environmentally conscious processes and materials, microfiber leather is free from harmful plasticizers, aligning with sustainable and health-conscious design trends. 5. Stable Coloration and Versatile Finishes Available in a wide range of textures and colors—matte, glossy, embossed, or leather-like grain—this material supports diverse design aesthetics. 6. Easy Maintenance Microfiber leather resists stains and is simple to clean, making it practical for daily use and long-lasting performance. ________________________________________ Drawbacks of Microfiber Leather 1. Higher Cost Due to its complex production process, microfiber leather is generally more expensive than standard PU leather. 2. Limited Heat Resistance Prolonged exposure to high temperatures may cause deformation or aging of the material; avoid direct sunlight or heat sources. 3. Moderate Water Resistance While it offers splash protection, untreated microfiber leather can still absorb moisture over time, potentially affecting structure and integrity. 4. Difficult to Repair Surface scratches or abrasions are not easily restored, unlike genuine leather which can often be conditioned or professionally repaired.

Jul 09.2025

Customized Hardware

Customized Hardware: Tailored Metal Accessories for Brand Identity and Enhanced Functionality Customized hardware refers to bespoke metal fittings designed to meet specific brand requirements, including zipper pulls, buckles, rivets, tags, chains, and more. These details not only improve bag functionality but also significantly elevate the product’s overall quality and brand recognition. ________________________________________ Key Features: 1.Exclusive Design Style Unique hardware shapes and logo engravings crafted to reflect the brand image and product positioning, showcasing professionalism and refined taste. 2.Various Material Options Common materials include brass, stainless steel, zinc alloy, and aluminum alloy, all offering excellent corrosion resistance and durability. Lightweight materials are also available to reduce bag weight. 3.Diverse Surface Treatments Electroplating finishes such as bright silver, antique bronze, rose gold, matte black, as well as brushing, polishing, sandblasting, and painting to fulfill different aesthetic and durability needs. 4.Precision Craftsmanship and Quality Control High-precision molds and advanced manufacturing equipment ensure every piece of hardware maintains consistent size, intricate details, and clear engraving. 5.Functionality and Safety Beyond aesthetics, customized hardware is engineered for strength, wear resistance, and safety—ensuring smooth zipper operation and secure fasteners to enhance user experience. ________________________________________ The Value of Customized Hardware: 1.Brand Differentiation Unique hardware design is a vital element of brand identity, helping to shape a distinctive style and elevate brand value. 2.Enhanced Product Premium Feel Exquisite hardware details boost the overall bag quality, attracting high-end consumers. 3.Increased Product Durability High-quality hardware components improve bag longevity and usage life

Cooperative Partner

ROBINMAY

雅詩蘭黛

NET

VEMAR